|

Nickel-Metal Hydride (NiMH) - Battery Charging:

It's important to maintain the batteries within the telemetry unit, especially for equipment that is stored for a period of time. There are various types of chargers available for batteries (able to run charge & discharge cycles) depending on the battery specifications. The charger that we use for the Adcon Telemetry equipment, will automatically run 'charge & discharge cycles' There is also a direct connection cable to the Logger, so you don't have to open the telemetry cover. LED lights indicate the battery state and simple charging instructions also come with the product. |

|

Telemetry Equipment disconnection & storage:

If your telemetry equipment has to be removed from a monitoring site, an important thing to do is - turn the telemetry unit off. This sounds simple enough but you would be surprised the number of people that forget at the time......The main reason is that the logger still reads the sensors and then communicates it's data to the base station, as a result the battery runs flat (no solar charge) and next time the unit is reinstalled....there's a problem. Turning off the logger - Adcon Telemetry equipment

|

|

Silica Gel Bags:

It's important to maintain the sensors and or other electronics located a telemetry unit. One useful way of doing this is by putting Silica Gel bags with the electronics and making this part of of a regular maintenance program. Silica gel are found in all sorts of products because silica gel is a desiccant -- it adsorbs and holds water vapor. Silica gel can adsorb about 40 percent of its weight in moisture and can take the relative humidity in a closed container down to about 40 percent. Once saturated with water, the gel can be regenerated by heating it to 120 °C (250 °F) for two hours. |

|

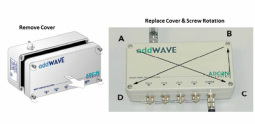

Battery Replacement:

If you need to replace a battery in your Adcon telemetry unit,

|

|

Soil Moisture C-Probe - Breather Vent:

It's important to maintain the soil moisture sensors and electronics located inside the access tube of a soil moisture probe that has removable sensors. One useful way of doing this is by adding a breather vent to equalise the pressure in the access tube and limit the level of condensation build-up. This improves sensor reliability and reduces maintenance costs. |

|

Sensor Cable - Protection:

Unfortunately cables can be damaged by either vermin or sometime accidents just happen. A cost effective way of reducing the possibility of this occurring is by using some type of cover or sheath over the cable and or sensor itself. Flexible conduit is an easy way to protect cables, simple to use and also easy to source. This will improve the reliability of the data coming from the monitoring site as well as reducing maintenance costs. |

|

Equipment Visibility:

This may sound basic enough but it can often be overlooked and be the cause of hardware damage and costly repairs. If the telemetry equipment is located in field with the potential for it to be damaged by other equipment, then we strongly suggest that in addition to the standard installation, some type of extra site identification be used:

|